Hands-on Manufacturing Excellence course (MEC)

About this course

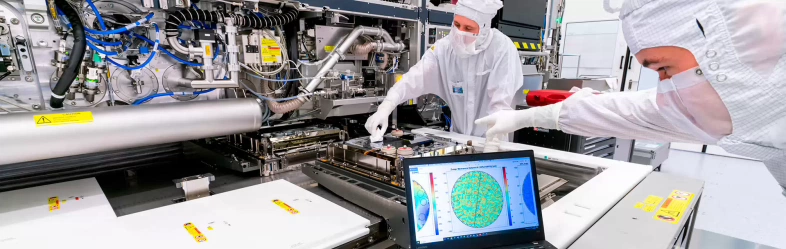

Hands-On Manufacturing Excellence Course (MEC), hands-on training program designed to enhance your skills in manufacturing. This immersive 9-day program will equip you with the essential tools and techniques required to excel in the manufacturing industry. Over the course of the program, you will work in team-settings in a simulated Learning Factory, building and optimizing manufacturing lines in a competitive and collaborative environment. You will also visit real factories, meet industry experts, and build a valuable professional network.

Key benefits

- Hands-On Learning: Practical challenges and real-world simulations

- Collaborative Environment: Team-based problem solving.

- Industry-Recognized Certifications: Enhance your professional qualifications.

- Networking Opportunities: Connect with peers and industry experts.

Learning outcomes

The Hands-On MEC provides hands-on training in four interconnected toolkits, ensuring participants learn both the theory and practical application, driving organizational success and personal development.

- Building on strengths in tangible tasks and tools, the Process and Process Control Toolkits invite participants to think on the next higher, more abstract level. These toolkits provide process-oriented thinking and tools to design, manage, and improve manufacturing processes, control, and quality systems.

- To identify areas where innovation and optimization are most beneficial, building confidence in the practical application of math is key. The Data Analysis and Statistics Toolkits teach participants to use crucial data analysis and statistical tools to uncover inefficiencies.

- Identifying problems problems and opportunities is just the first step; turning them into actionable solutions is crucial. The Engineering Toolkits empower participants to utilize systematic problem-solving and design methods to transform insights into solutions.

- Since implementing solutions cannot be achieved in isolation and always involves multiple stakeholders, the Collaborative Skills Toolkits enhance participants’ abilities to effectively communicate and execute improvement initiatives, fostering a cohesive and efficient work environment. Together, these toolkits provide a comprehensive skill set aligned with both organizational goals and individual learning needs.

“During the course, we set up several production lines, which closely

mirrored real-life scenarios. The optimizations we made during the

training were almost directly transferable to our actual work.

While I expected some improvements using the tools, I was astonished

by how effective we became—ultimately two or three times more

efficient. This truly surprised me.”

— Sander Schoonderbeek, Vehicle Integration Leader at Hyster-

Yale Group, MEC NLQF 7

Practical information

- Duration: 9 days (divided into modules)

- Timing: September - October 2025

- Participants: 60

- Language: English

- Entry Level: NLQF Level 4 and higher

- Certification: Microcredential NLQF 5 (AD level) and Microcredential NLQF 7 (Master level)

- Learning Environment: Simulated Learning Factory and Factory Visit

- Location: Brainport Industries Campus (BIC), Eindhoven

Key dates

> Kick-Off Event: September 8, 2025 (9.00-17.00)

> Precision Manufacturing Session: September 15-18, 2025 (9.00-17.00); closure on September 18 is until 19.30

> Operational Excellence Session: September 22-25, 2025 (9.00-17.00)

> Final Event: September 25, 2025 (17.00-21.00)

> Factory Visit: Oktober 2025 (9.00-13.30)

Fees and application

- Course Fee: Price on request

- Application Deadline: 1 September 2025

- How to Apply: send an e-mail to engineering-pro@fontys.nl

- Pre-registration: Open now for individual participants and teams.